Deburring with MicroBlasting

MicroBlasting delivers pinpoint accuracy that allows you to attack a burr at its root without causing dimensional changes to the part. Whether you need to deburr PEEK spinal implants or cross-drilled holes in aerospace components, Comco’s MicroBlasting equipment provides an efficient solution.

Ready to process sample parts?

Sign me up!PEEK

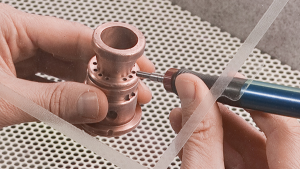

Unlike a knife, a rich abrasive stream at a low pressure follows the contours of the implant, covering a wider area in a single pass.

Polymers

Certain softer abrasives, like Sodium Bicarbonate, remove burrs quickly without damaging the underlying surface.

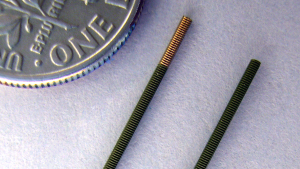

Bone Screws

Remove burrs while maintaining a sharp cutting edge. Can also create a compressive layer on the surface of the threads, which helps to improve the fatigue life.

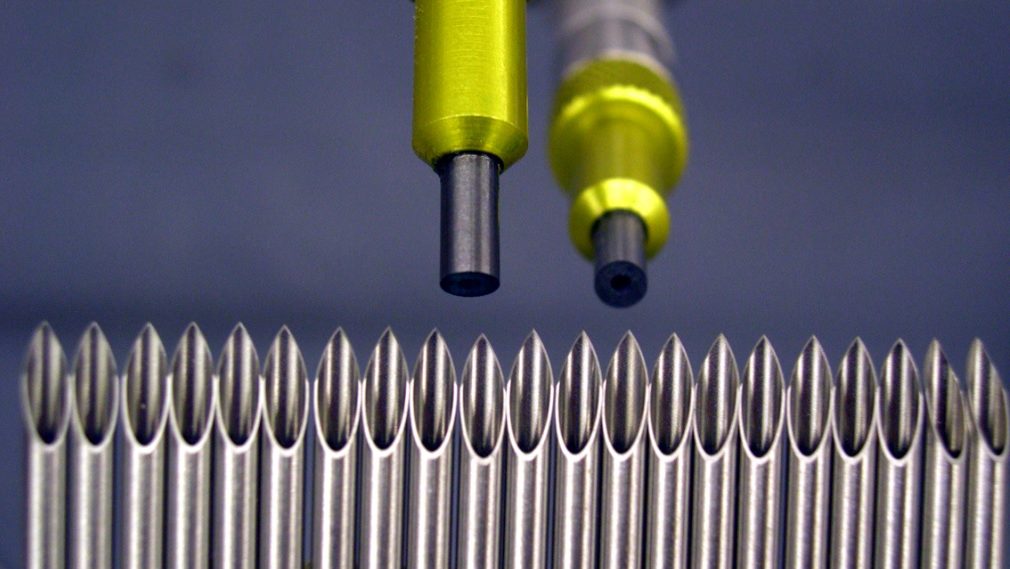

Metals

Titanium hardens as it heats up, making it tough to machine. MicroBlasting with glass bead gently removes burrs without changing part geometry.

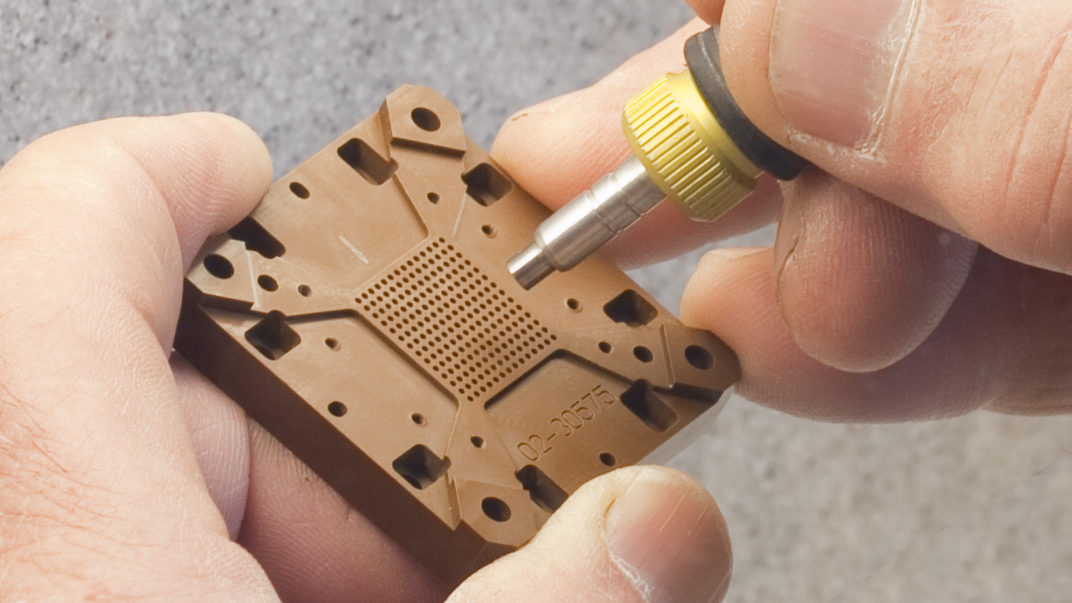

Nozzle Angle

Abrasive particles transfer the most impact energy when the nozzle is positioned at 90° to the target, but abrasive particles ricochet at this direct angle, crowding and slowing the stream. When cleaning or eroding surface material, hold the nozzle at or near a 75° angle to the target.

LEARN MORE

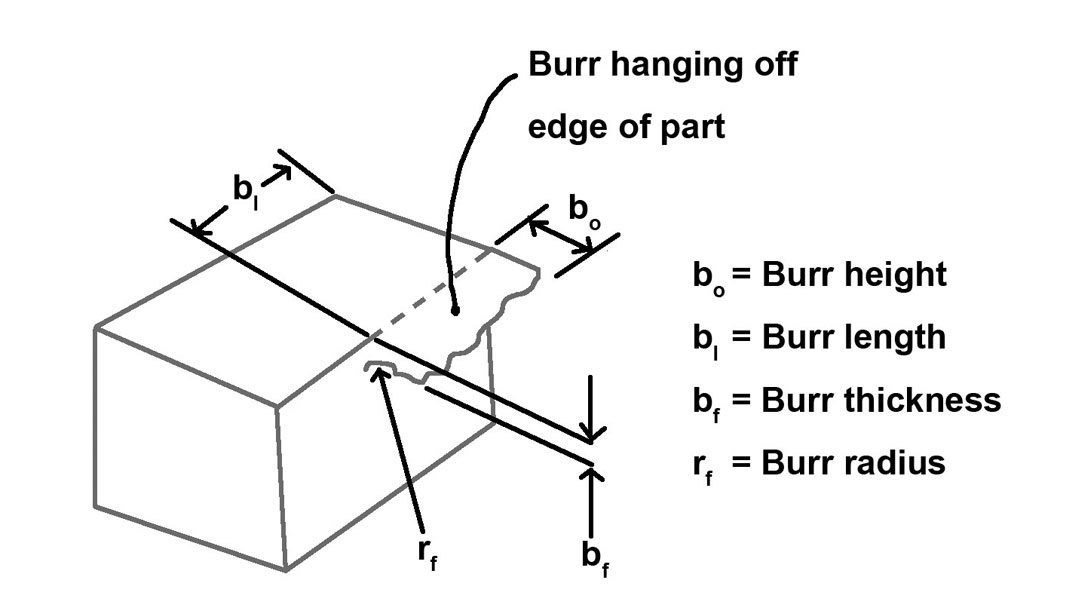

The Missing Measurements of Deburring

Are old burrs suddenly reappearing? Are burrs popping up in a new location on your part? Is a once-reliable deburring method starting to fail? Chances are, you’re missing a measurement. Manufacturing expert, LaRoux Gillespie, shares the deburring measurements often missed that lead to recurring problems and new burr formations.

Learn More

5 Factors that Lead to Successful Deburring

In this quick video lesson, we break down the 5 factors that impact most deburring applications. When you’re done, you’ll know how to deburr…better!

LEARN MORE

The Manual System

The AccuFlo® and ProCenter Plus package produces a steady flow of abrasive which ensures consistent results. It processes parts faster than most traditional micro-abrasive blasters, and it does so with greater powder efficiency. The AccuFlo is able to handle a wide-range of abrasives and suits most MicroBlasting applications.

Learn more

Automated Solutions

When a manual MicroBlasting system cannot provide the output or meet your tolerance requirements; Comco’s automated systems deliver all the benefits of a manual system with greater precision and efficiency. Both the Advanced Lathe and the JetCenter are designed for the steady processing of precision parts. Each automated system is customizable from a proven platform and delivered as a turnkey solution.

Learn moreWhy Choose Comco?

Do you know what sets a Comco micro-precision sandblaster apart from others? In short, It’s our modulator. This pulsing heart of our system transforms the technology from a dirt sprayer into a precision tool.

Learn moreMicroBlasting Capabilities Proven

We understand that MicroBlasting is a unique process that you may not be familiar with. The proof is in how MicroBlasting can improve your manufacturing process on your parts. Contact us to arrange for a demonstration.

-

An Experienced & Qualified Team

Engineers lead the process from concept to development. Our focus is on ensuring the process will work in production. We are as good at figuring out new applications as demonstrating what we have already done.

-

Our State-of-the-Art Lab

Our lab contains a complete range of MicroBlasting tools—from our manual stations to the fully programmable automated systems to run your samples. In addition, we have a complete inspection suite to document our results.

-

Comprehensive Results Ready for You

All results are captured in a clear and detailed report with pictures that you can take right back to your team along with the finished part.

-

Applied Engineering With a Deep Understanding of Industrial Manufacturing

Our engineers have a background in medical, aerospace, and the semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

Send us your sample Part!

MicroBlasting’s benefits can be a bit of a mystery. Our applications engineers have the experience and complete test facilities to process your parts. If you think MicroBlasting may be appropriate for your application, our team would love the opportunity to help you out.