Microblasting Nitinol Stents

Comco has over 25 years of experience working with the Nitinol you use in your medical device. From R&D to mass production, we have your solution. Our test facilities and applications engineers are available to help you optimize your process.

Contact usThe Process

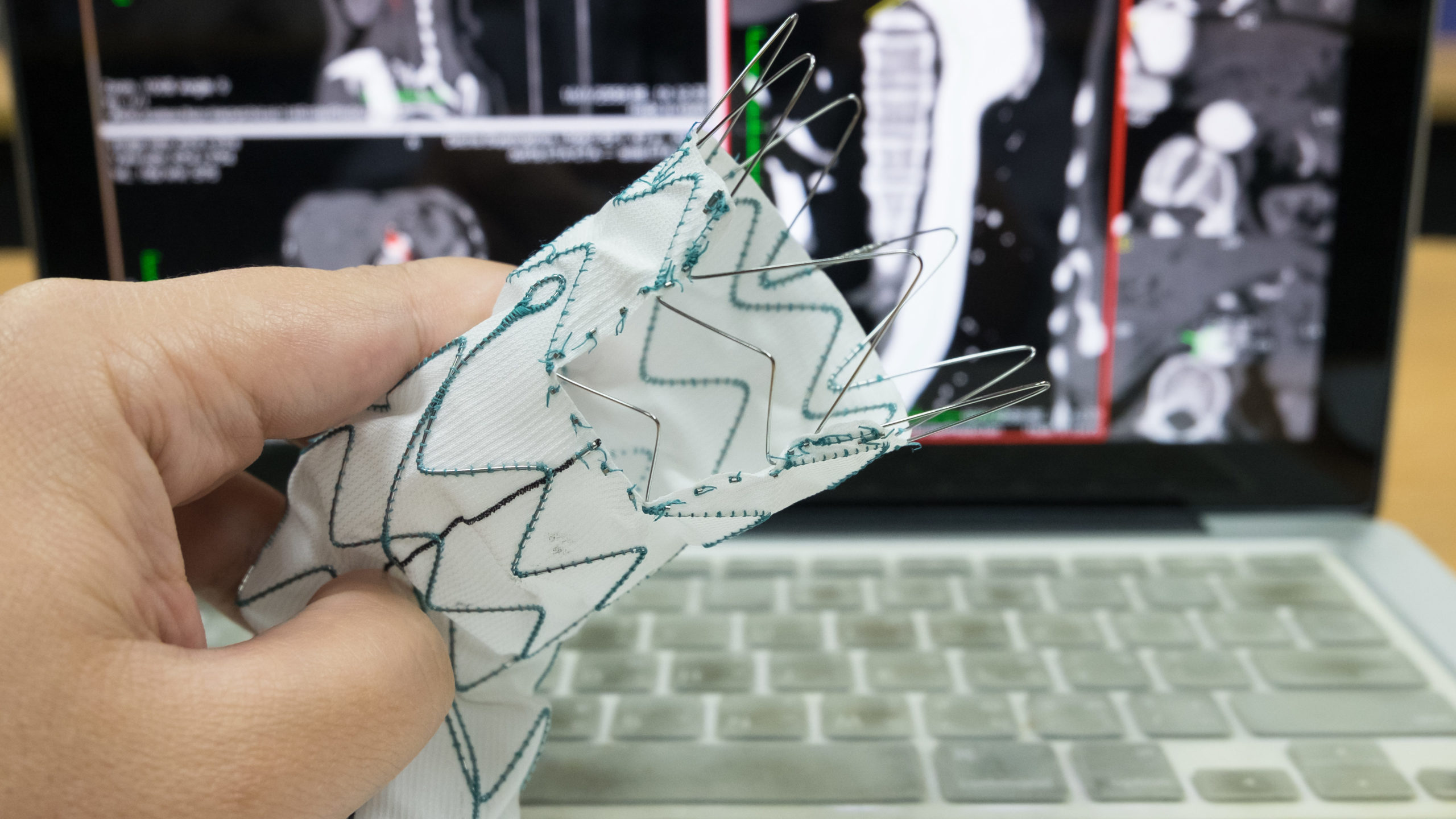

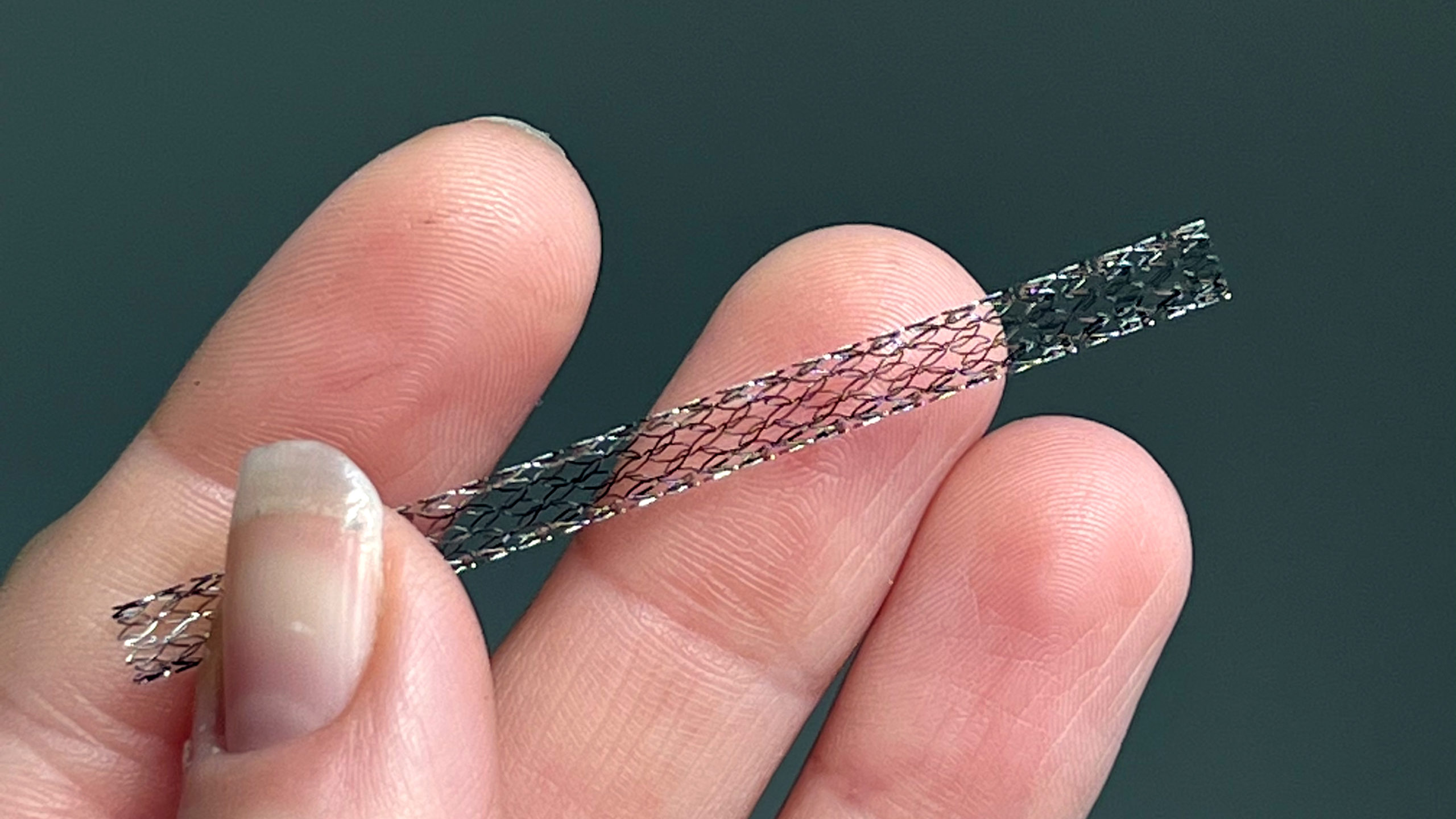

Laser machining or stamping of nickel-titanium alloys (Nitinol) creates surface defects, like oxide layers, heat-affected zones (HAZ), and pulse marks. The expansion process turns these defects into potential sites of crack propagation.

MicroBlasting removes these defects, imparting a textured finish to the surface of the device. While a matte finish may seem contrary to the goal of electropolishing, this uniform finish speeds the polishing process. The more uniform the texture, the shinier the polish.

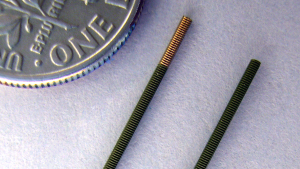

Nitinol requires a fine ceramic media like 17.5 µ aluminum oxide. The abrasive registers as a 9 on the Mohs scale of hardness which means that it effectively transfers energy to a brittle oxide layer and shatters it away quickly. Fortunately, the blocky shape of the aluminum oxide particles will not effectively cut into the ductile base material.

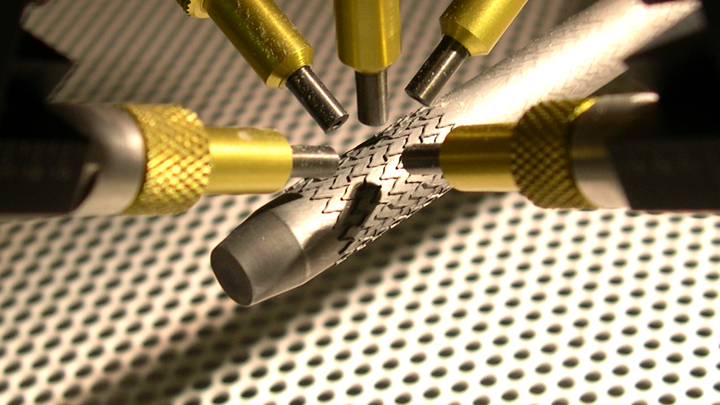

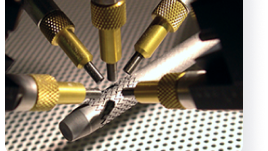

Due to volume and precision requirements, this application benefits from automation. Our Advanced Lathe and JetCenter platforms are able to follow the profile of a nitinol frame, ensuring uniform mass removal.

Ready to get started with MicroBlasting?

Contact UsBenefits of the Manual System

Comfortable

Ergonomic design reduces operator fatigue

Versatile

Flows a wide range of media

Consistent

Unique patented modulated abrasive feed

User Friendly

Easy to set-up and easy to maintain

Mobile

Casters allow for adaptive cell environments.

Clean and Quiet

Hepa filtration and customized fan box improves operation.

Cost-Effective

Our best deal for a turnkey solution

Benefits of the Automated System

Customizable

Offers a range of workholding and blast head options

Scaleable

Designed to grow from manual to fully automatic

User friendly

Intuitive user interface for programming and operation

Turnkey

Delivered production ready

Peace of mind

Fully documented and supported

Consistent

Unique patented modulated abrasive feed

Robust

Stable in Full Production

Your Partner for Industrial Engineering Solutions

We’ll work closely with you by applying our engineering skills to your problem, providing the process with our technologies, and sharing our accumulated expertise to develop solutions that are efficient and cost effective.

-

Applied Engineering with a Deep Understanding of Medical Parts

Engineering is at the core of Comco. Our engineers have a background in the medical, aerospace, and semiconductor industries. While we are experts at MicroBlasting, we can also “speak your language.”

-

Providing the process at no additional cost to you

Let us prove how a custom MicroBlasting process would work for you while sharing our engineering expertise up front, without charge.

-

Sharing our skills & knowledge throughout our partnership

We’ll share our engineering skills and knowledge at every step of our partnership. Advanced technical support continues beyond your initial purchase of our MicroBlasting systems, and we also offer assistance with new applications as they arise.

Send us your sample Part!

MicroBlasting’s benefits can be a bit of a mystery. Our applications engineers have the experience and complete test facilities to process your parts. If you think MicroBlasting may be appropriate for your application, our team would love the opportunity to help you out.