What is MicroBlasting?

Comco MicroBlasting Systems are used across multiple industries to texture, deburr, etch and machine a wide variety of materials—even the most delicate. We’ll work closely with you to land on custom solutions for your design, engineering, and manufacturing needs.

Ready to process sample parts?

Sign me up!The capabilities of MicroBlasting

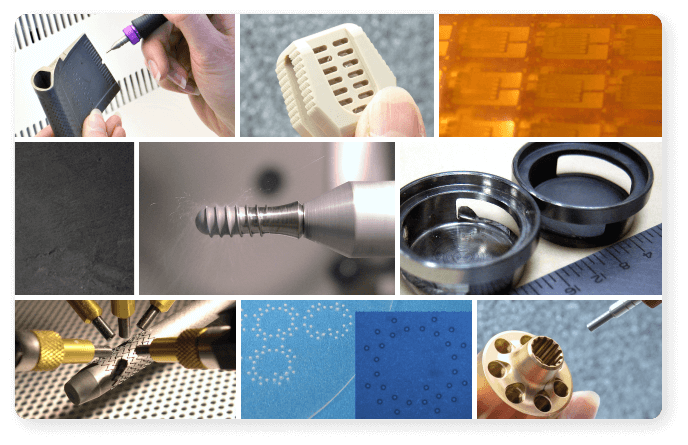

Whether it’s deburring screws, needles or implants, removing dross from laser cut stents or machining groves in hydrodynamic seals, MicroBlasting technology has a wide range of uses.

Solutions for Every Application

Select a MicroBlasting process below to see examples of related manufacturing solutions

Dental Implants

Texturing a dental implant accelerates osseo-integration.

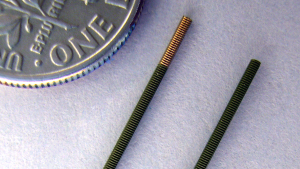

Bone Screws

Texturing the surface of the screw head improves the mechanical bond with its mating fixation device.

Ceramic Wafers

Texture the surface of a silicon wafer to improve light absorption and decrease reflection.

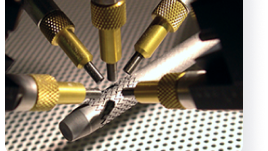

Multi-axis Load Cells

MicroBlasting is used to cut through the black anodize and texture the surface to improve the bond with flex circuitry.

Nitinol Stents

Remove surface defects without compromising the integrity of the delicate underlying material.

Pacemaker Headers

Remove excess encapsulation that seeps out from the header during installation.

Reconditioning Turbine Blades

Refurbish either land-based gas or jet-engine turbines by removing the protective oxide layer.

Metalization on ceramic components

Remove metalization on ceramic components to improve electrical isolation.

PEEK

Unlike a knife, a rich abrasive stream at a low pressure follows the contours of the implant, covering a wider area in a single pass.

Polymers

Certain softer abrasives, like Sodium Bicarbonate, remove burrs quickly without damaging the underlying surface.

Bone Screws

Remove burrs while maintaining a sharp cutting edge. Can also create a compressive layer on the surface of the threads, which helps to improve the fatigue life.

Metals

Titanium hardens as it heats up, making it tough to machine. MicroBlasting with glass bead gently removes burrs without changing part geometry.

Lens Engraving

Etch serial numbers into lenses for ring laser gyros without creating micro-cracks.

MicroFluidics

Machine vias in glass and silicon to create through holes for MEMS devices.

Hydrodynamic seals

Etch shallow channels into the groves or channels of the surface of a seal to crate an air bearing.

Thermocouples

Remove MgO to expose contacts for bonding on heat-sensing harnesses.

Materials We’ve Worked With

MicroBlasting is an effective process for a variety of materials and compositions. Click below to view and search materials we commonly work with.

Browse Materials

Materials We’ve Worked With

MicroBlasting is an effective process for a variety of materials and compositions. Click below to view and search materials we commonly work with.

Can’t find what you’re looking for? Contact us and we’ll let you know how your material(s) can be used with our MicroBlasting technologies.

Aluminum

Brass

Bronze

Copper

Ceramic

Glass

Graphite

Inconel

Kovar

Nitinol

Polypropylene

PEEK

PTFE

Silicon

Stainless Steel

Titanium

Brass

Send us your sample Part!

MicroBlasting’s benefits can be a bit of a mystery. Our applications engineers have the experience and complete test facilities to process your parts. If you think MicroBlasting may be appropriate for your application, our team would love the opportunity to help you out.